The Natural Ink Printer

Project details

- Year

- 2024

- Programme

- Bachelor – Graphic Design

- Practices

- Commercial Practices

- Minor

- Materials & Systems

The rise of industrialisation significantly changed printing processes, leading to mass-produced, uniform-looking prints that lack the aesthetics of handcrafted printing techniques. Industrialisation prioritised speed and consistency. Humans could not compete with machines and became less involved in the printing process. Additionally, globalization connected the local identities of goods, thereby replacing the diversity of different places and cultures.

This project questions the priorities of the factory system and wonders if a unique and handmade-looking print could be made while still using a digital printing machine. By replacing the synthetic inks of the inkjet printer with traditional natural inks, the project aims to get back a bigger participation within the printing process and bring back the unique qualities that prints used to have.

The result is a process that highlights the potential and limitations of combining traditional craftsmanship with digital technologies. It can be seen as a critique of modern society and industrial systems.

An attempt to bring back the craft in digital printing

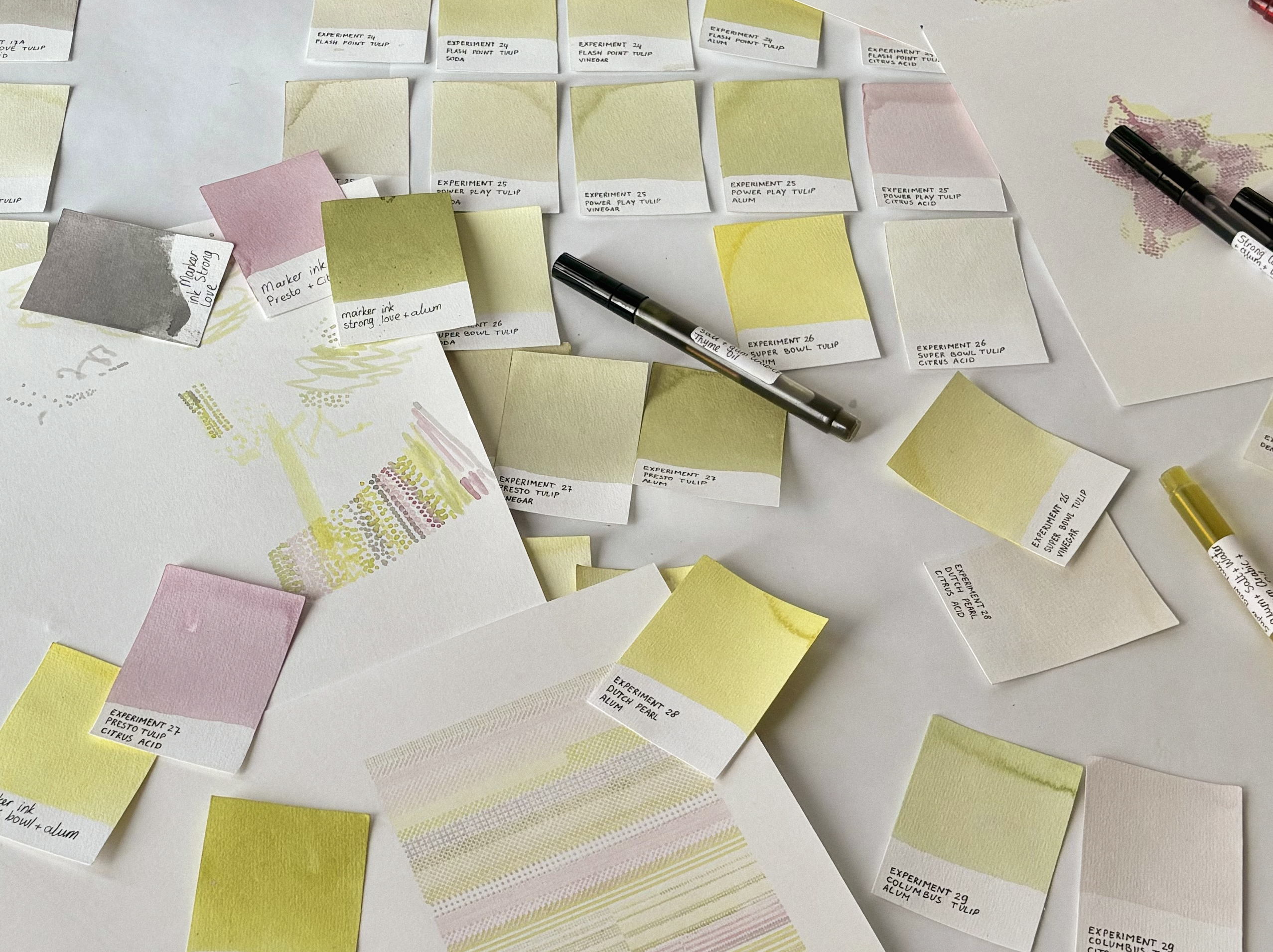

THE MATERIAL

The first phase of this project focused on crafting natural inks by hand. This involved researching traditional ink-making techniques and experimenting with various natural materials. The project shows a broad research in which with various materials were tested and ended with making ink from the tulip waste of a local tulip farmer. This method fosters a deeper connection to the materials used, as the colors are tied to the local environment and seasonal changes.

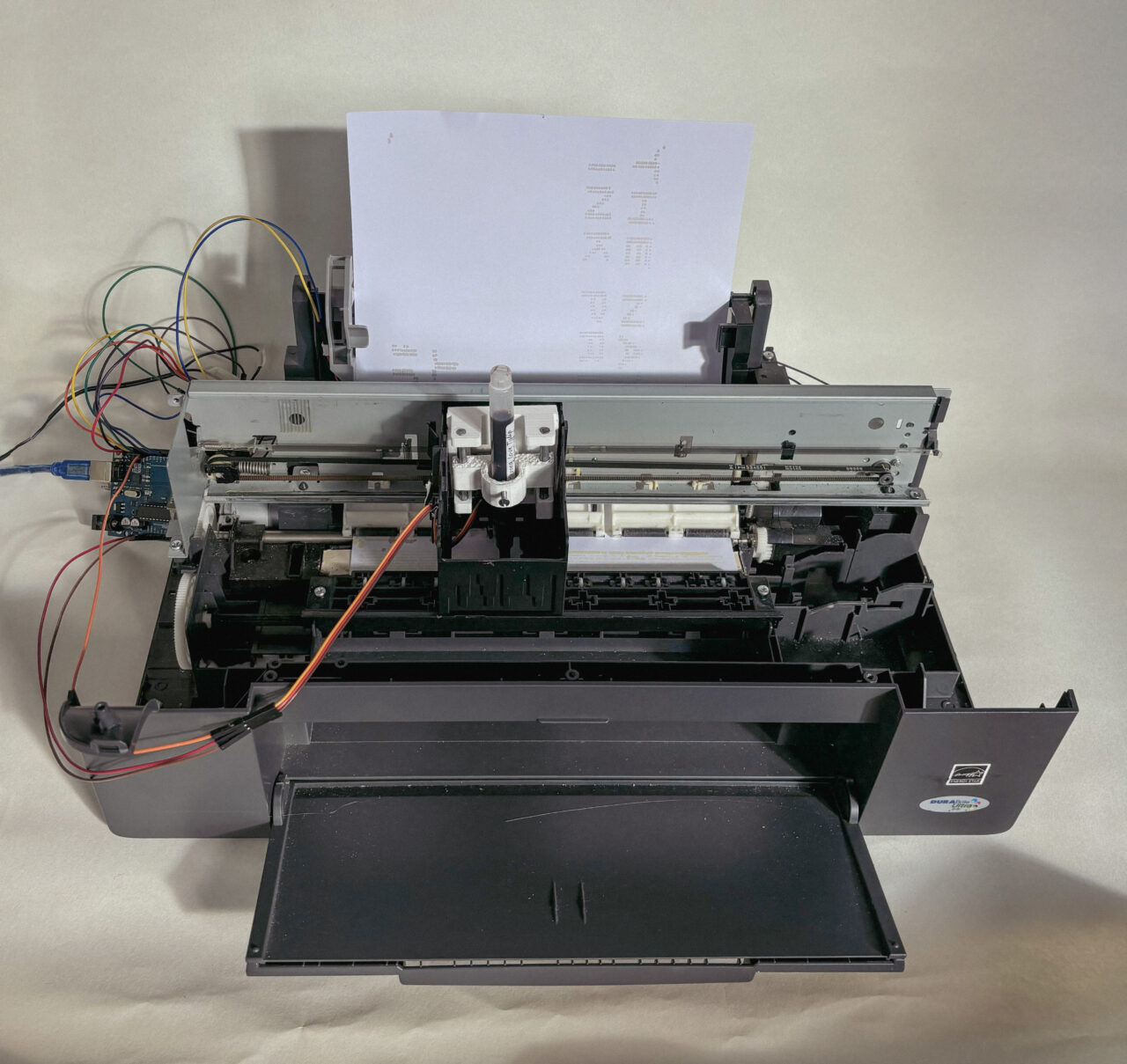

THE SYSTEM

The second phase explored the integration of these natural inks into inkjet printers. Despite several tests, this project was not able to use the tulip ink directly into inkjet printers due a lack of knowledge that could not be gained because of the centralized knowledge system.

MATERIAL & SYSTEM

Inkjet printers create images using a “drop on demand” method, where tiny droplets of cyan, magenta, yellow, or black ink are deposited on paper. However, the system of inkjet printing was not able use the tulip ink, while markers were able to draw with the ink. To be able to print with the markers, the inkjet printer had to be modified into a penplotter. By commanding the pen plotter to draw dots on the paper, the technique of drop on demand was mimicked.

Do you want to see more of my projects? www.brittrozendaal.com

Or would you like to get in contact? E-mail me: britt-r@live.nl or dm me via instagram!